Gases Industry

During the last few years LICO GmbH developed several custom machines for the gas-producing industry. These are machines that allow for maintenance of gas cylinders. In addition, we also offer systems for homogenising gas mixtures. These machines are fully automatic and are already exported across the EU.

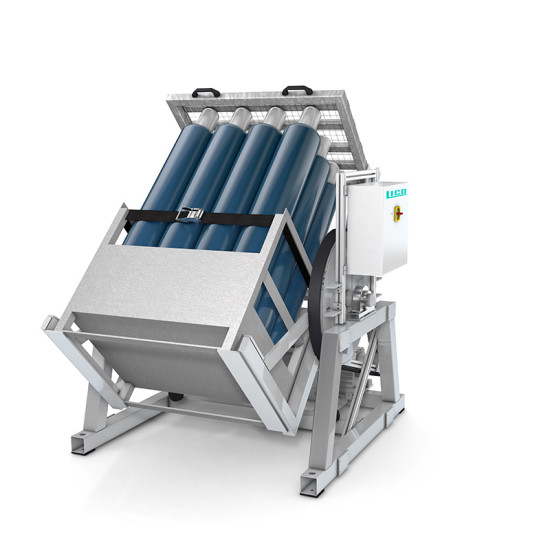

Gas Homogenisation Machine for single bottles and bottle rack

FULLY AUTOMATED

SEMI AUTOMATED

https://www.youtube.com/watch?v=JS_-6pY7fx0

Gas Mixtures in a 12-piece cylinder bundle, as well as loose cylinders on a transport pallet, can be homogenised with the gas mixing device. The device is adjusted for the specific version of the bundle stand and Bottle rack provided by the customer. The machine is surrounded by a safety fence with electrically controlled safety door.

The standard version of the machine is designed for pallets with floor dimensions

980 mm x 800 mm. For another dimensions the basic design must be changed

a little bit.

SPECIFICATIONS:

length 3590 mm

Width 2410 mm

Height 2660 mm

Total weight 2120 kg

Weight 20 000 N

Rolling device

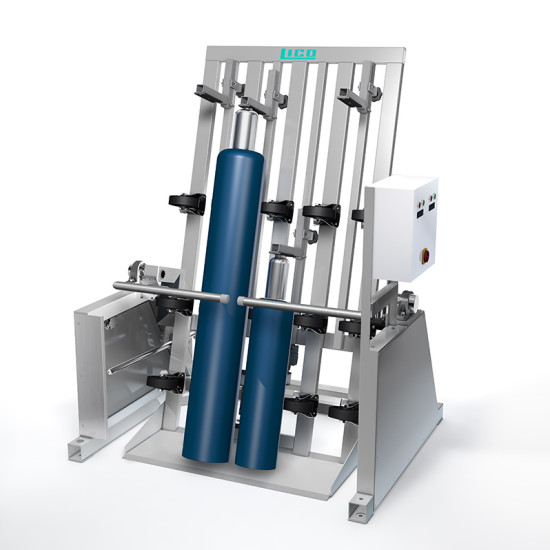

SEMI AUTOMATED

Gas mixtures with 4, 5 or 6 steel cylinders in the sizes Ø 100 mm – 250 mm and lengths 900 mm – 1,850 mm can be homogenised with the mixing device for gases by rotating them along the longitudinal axis of the cylinders.

In the version for potentially explosive rooms the switch box is attached outside the explosion risk (Ex) area. Drives, limit switches and operating console are equipped for explosion protection class Eexde II T4.

SPECIFICATIONS:

Length 3 590 mm

Width 2 410 mm

Height 2 660 mm

Total weight 2 120 kg

Weight 20 000 N

Valving Machine for insertion and removal

MACHINE TO REMOVE AND INSERT VALVES OF STEEL CYLINDER

SPECIFICATIONS:

Features:

– Adjustable torque moments

– Diameter of cylinders 110 mm – 300 mm

– For different nuts available

– Lifting – unit for cylinders

– Construction normal and EX

The system consists of the following components:

– machine frame

– drive unit

– clamping device

– machine control system

Divisions